For our April style competition, my homebrew club decided to try a Breslau-Style Pale Schöps. I had never heard of this until my club president brought this up as an option, and a bit of searching online finds virtually nothing. This is a historical style, native to the area of Breslau (now Wrocław, Poland). The Brewer’s Association added it to their style guide for the GABF a few years back, which I can only imagine must have been a special favor for someone, because there just ain’t any commercial examples out there now.

In any case, I only found a handful of recipes online, and many (all?) of these were by people asking, “So, I made up this recipe and does it look plausible…” This meant I decided to just use what I’ve learned over the years, and try and put my own recipe together.

From what I read about the style, it should be mostly wheat malt in the grist (up to 80%), with a bready flavor and aroma aspect and a full body. Although this is a wheat ale, it wasn’t supposed to have German wheat ale yeast–instead, a fruity character was described, without phenols. Hops are in the background on this, too.

With all of this information, I put together a grain bill that was mostly wheat malt (~70%), backed up by equal parts pilsner and biscuit malt. I elected to go with a German ale yeast, the classic WLP029. For my grains, I wanted to go with European malts, choosing those from Viking because at least some are sourced from Poland. This seemed appropriate for the brew! I had no idea if I would like this batch or not, so I aimed for 3 gallons instead of the full 5.

The name is a German-ish (highly inauthentic and untranslatable) pun on “Sheep’s Head,” just because I thought it sounded funny and vaguely like the word “Schöps.”

Schoepshead Pale Schöps

- 6 lb. wheat malt (Viking)

- 1 lb. biscuit malt (Dingemans)

- 1 lb. pilsner malt (Viking)

- 1 lb. rice hulls

- 2 oz. Hallertauer Mittelfrueh hop pellets (2.7% alpha), 35 minute boil

- 1 Whirlfloc tablet, 10 minute boil

- 1 tsp. Fremax yeast nutrient, 10 minute boil

- 1 pkg. German Ale/Kolsch yeast (White Labs, WLP029)

Target Parameters

- 60 minute infusion mash, 153°, batch sparge

- 1.065 o.g., 1.016 f.g., 6.6% abv, 24 IBU, 8 SRM

- Claremont tap water

Procedure

- 48 hours in advance, I made a 0.65L starter with the yeast, and cold crashed for 24 hours.

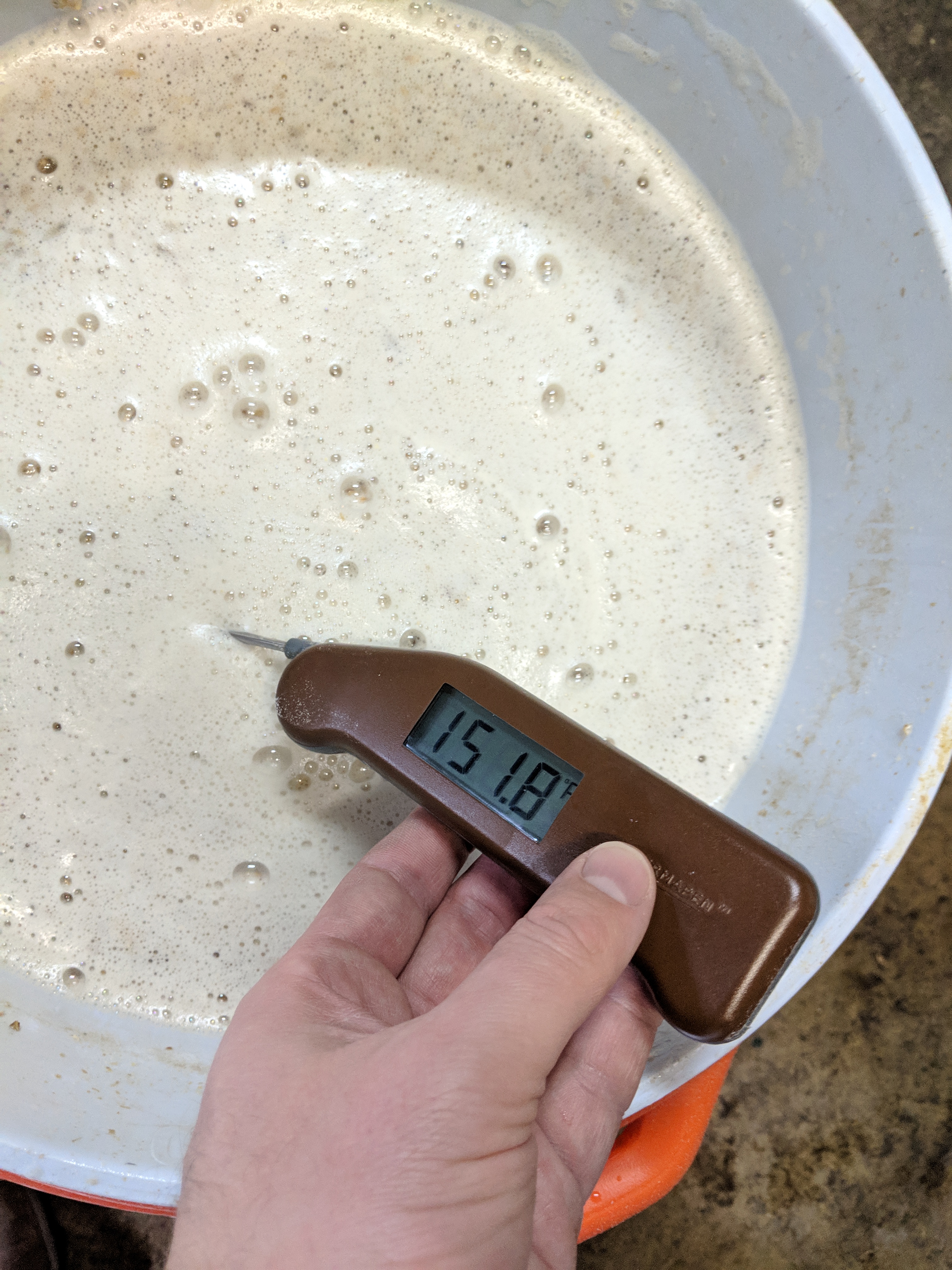

- I mashed in with 3.25 gallons of water at 165°, to hit a 154° mash temperature. I let this sit for 60 minutes, and it was down to 151° by the end. I added 0.3 gallons of water at 185°, let sit for 10 minutes, vorlaufed, and collected first runnings.

- Then, I added 2.25 gallons of water at 185°, let sit for 10 minutes, vorlaufed, and collected the second runnings.

- In total, I collected 4.3 gallons of runnings at a gravity of 1.047. This was only 67% efficiency; it put me well below my target (1.053), but it’s not a surprise given the large amount of wheat in the bill.

- I boiled for 60 minutes, adding hops and yeast nutrient per the schedule. After 60 minutes, I chilled the wort and transferred to the fermenter.

- I brewed this beer on March 30, with a starting gravity of 1.060. I fermented the beer a 68°, and gravity was down to 1.014 by 2 April. On 9 April, gravity was 1.010. I kegged the beer at this point; it had reached 6.6% abv.

Tasting

- Aroma

- Very bready, with a slight fruitiness behind that. No hop aroma.

- Appearance

- Persistent white and very fine head. Beer itself is copper color, with a decent amount of haze.

- Flavor

- Lightly fruity on the front, with a nice rounded bready, malty flavor behind that. Hop bitterness is medium-low, with a nice smooth finish.

- Mouthfeel

- Great body on this, with moderately high carbonation. The finish is nice and extended, pleasantly balancing the malt and hops.

- Would I brew this again?

- This is a really nice beer! I could see myself brewing this recipe again….I wasn’t sure how I’d like this, and it has turned into a pretty enjoyable brew. The flavor is really nice, and it’s a highly drinkable style for its level of alcohol. It’s a great bridge between the beers of winter and the beers of summer. I can’t say there’s anything I’d really change, either to keep it more to style or to make it more to my palate.

- Overall

And…the beer won first place in our club competition!

Many of my recent brews have explored styles that are new to me–

Many of my recent brews have explored styles that are new to me–